12 volt electric fuel pumps are essential components in modern fuel systems, providing the necessary pressure to deliver fuel to the engine. These pumps offer a range of advantages over mechanical fuel pumps, making them the preferred choice for many applications.

In this comprehensive guide, we will explore the world of 12 volt electric fuel pumps, from their types and installation to their performance and efficiency.

Whether you’re a seasoned mechanic or a curious enthusiast, this guide will equip you with the knowledge you need to understand, select, and maintain 12 volt electric fuel pumps. Join us as we delve into the fascinating world of fuel delivery systems.

Introduction: 12 Volt Electric Fuel Pump

A 12-volt electric fuel pump is a device that uses electrical energy to pump fuel from a fuel tank to an engine. It is commonly used in vehicles, particularly those with fuel-injected engines. Electric fuel pumps offer several advantages over mechanical fuel pumps, including improved fuel efficiency, reduced emissions, and quieter operation.

Advantages of Electric Fuel Pumps

- Improved fuel efficiency:Electric fuel pumps are more efficient than mechanical fuel pumps, as they do not rely on the engine’s camshaft to operate. This can lead to improved fuel economy, as the engine does not have to work as hard to pump fuel.

- Reduced emissions:Electric fuel pumps can help to reduce emissions by providing a more precise fuel delivery to the engine. This can lead to cleaner combustion, which can result in reduced emissions of harmful pollutants.

- Quieter operation:Electric fuel pumps are much quieter than mechanical fuel pumps, as they do not produce the same level of noise and vibration.

Disadvantages of Electric Fuel Pumps

- Cost:Electric fuel pumps are typically more expensive than mechanical fuel pumps.

- Reliability:Electric fuel pumps are not as reliable as mechanical fuel pumps, as they can be more susceptible to failure due to electrical problems.

Types of 12-Volt Electric Fuel Pumps

12-volt electric fuel pumps are essential components in many fuel systems, providing the necessary pressure to deliver fuel from the tank to the engine. They come in various types, each with its unique characteristics, advantages, and drawbacks. Understanding the different types of 12-volt electric fuel pumps is crucial for selecting the most suitable one for your specific application.

The primary types of 12-volt electric fuel pumps include inline, submersible, and gerotor pumps. Inline pumps are mounted outside the fuel tank and are commonly used in carburetor-equipped vehicles. Submersible pumps, as the name suggests, are submerged in the fuel tank and are often found in fuel-injected vehicles.

Gerotor pumps, characterized by their crescent-shaped rotors, are known for their high efficiency and durability.

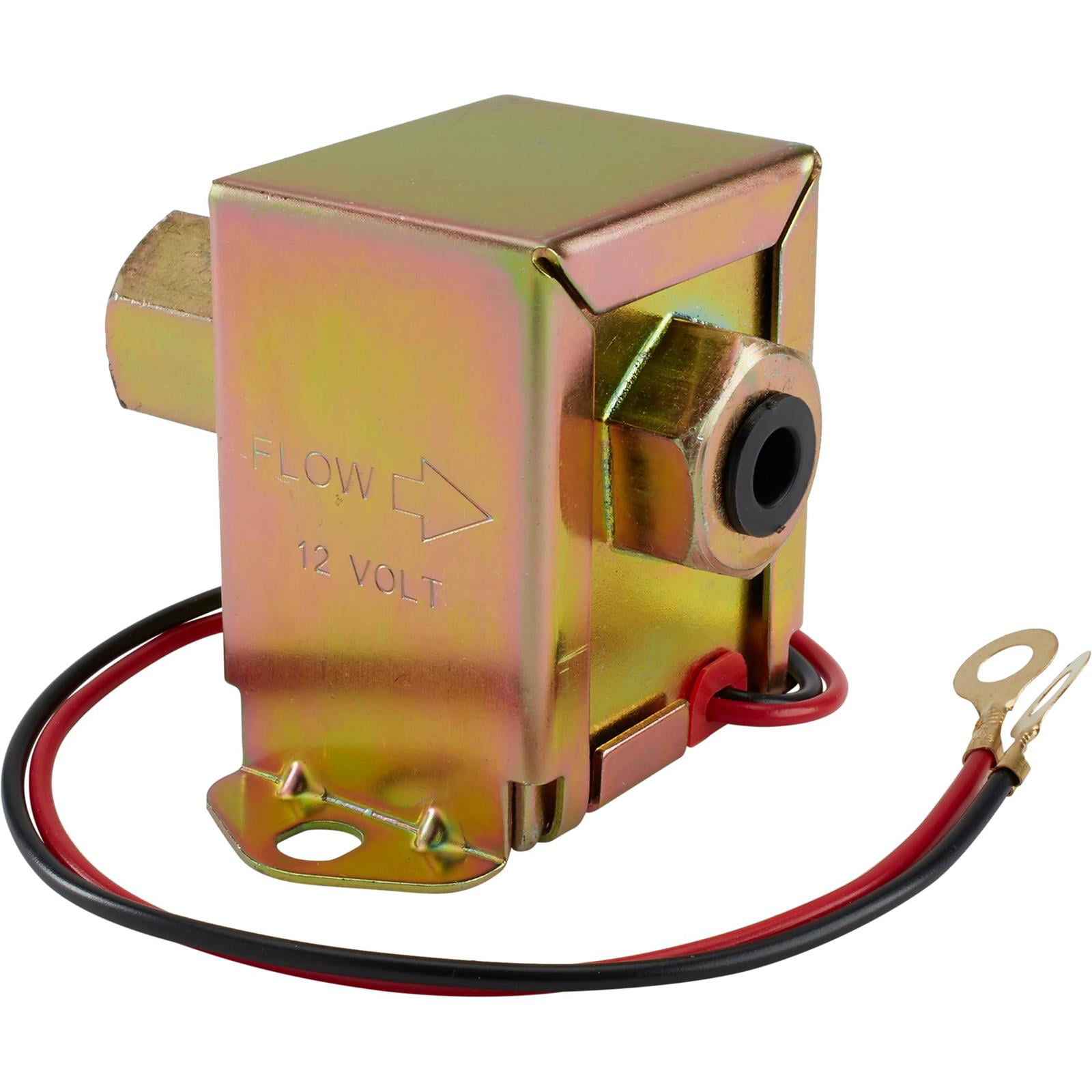

Inline Fuel Pumps, 12 volt electric fuel pump

Inline fuel pumps are external pumps that are installed in the fuel line between the fuel tank and the engine. They are relatively easy to install and maintain, making them a popular choice for DIY enthusiasts. Inline pumps are available in various flow rates and pressures, allowing you to select the one that meets your specific requirements.

Submersible Fuel Pumps

Submersible fuel pumps are designed to be submerged in the fuel tank, providing a continuous supply of fuel to the engine. They are typically quieter than inline pumps and are less prone to vapor lock, making them ideal for fuel-injected vehicles.

Submersible pumps are often equipped with filters to prevent debris from entering the fuel system.

Gerotor Fuel Pumps

Gerotor fuel pumps utilize a crescent-shaped rotor and a gear to create a pumping action. They are known for their high efficiency and durability, making them a popular choice for high-performance applications. Gerotor pumps are also relatively compact, allowing for easy installation in tight spaces.

Installation and Wiring

Installing a 12-volt electric fuel pump requires careful planning and attention to detail. Proper installation ensures optimal performance and prevents potential issues.

To install the fuel pump, follow these steps:

Mounting the Fuel Pump

- Choose a suitable location for the fuel pump, ensuring it is easily accessible for maintenance and replacement.

- Mount the fuel pump securely using the provided mounting brackets or hardware.

- Ensure the fuel pump is oriented correctly, with the inlet and outlet ports facing the appropriate directions.

Fuel Line Connections

- Connect the inlet port of the fuel pump to the fuel tank using a flexible fuel line.

- Secure the fuel line with clamps or fittings to prevent leaks.

- Connect the outlet port of the fuel pump to the fuel line leading to the engine.

Electrical Wiring

- Connect the positive (+) terminal of the fuel pump to the vehicle’s electrical system, using a fused power wire.

- The fuse protects the fuel pump from electrical overloads and short circuits.

- Connect the negative (-) terminal of the fuel pump to a suitable grounding point on the vehicle’s chassis.

- Ensure all electrical connections are secure and properly insulated to prevent shorts or arcing.

Testing and Priming

- Before starting the engine, turn the ignition key to the “ON” position without cranking the engine.

- This allows the fuel pump to prime the fuel system, filling the fuel lines and injectors.

- Check for any leaks or abnormal noises during the priming process.

Maintenance and Troubleshooting

Maintaining and troubleshooting a 12-volt electric fuel pump are crucial for ensuring optimal performance and longevity. Regular maintenance involves inspecting and cleaning the pump, replacing filters, and checking connections.

Troubleshooting Tips

If you suspect a fuel pump issue, start by checking the fuel pressure. Low fuel pressure can indicate a failing pump. Inspect the fuel lines for leaks or blockages. A clogged fuel filter can also restrict fuel flow.

Signs of a Failing Fuel Pump

Common signs of a failing fuel pump include difficulty starting, engine stalling, and reduced power. The pump may make excessive noise or vibrate abnormally. Addressing these issues promptly can prevent further damage and ensure the smooth operation of your vehicle’s fuel system.

Performance and Efficiency

12-volt electric fuel pumps deliver impressive performance and efficiency in fuel delivery systems. Their ability to generate high flow rates and pressure, coupled with their compact size and low power consumption, makes them ideal for a wide range of applications.

Several factors influence the performance of 12-volt electric fuel pumps, including flow rate, pressure, and voltage. Flow rate measures the volume of fuel delivered per unit time, typically expressed in gallons per hour (GPH). Pressure refers to the force exerted by the pump to push fuel through the system, usually measured in pounds per square inch (PSI).

Voltage, on the other hand, represents the electrical potential that drives the pump’s operation.

Optimizing Fuel Pump Efficiency and Longevity

To maximize the efficiency and longevity of 12-volt electric fuel pumps, consider the following recommendations:

- Proper Sizing:Select a pump with a flow rate and pressure that meet the specific requirements of your engine and fuel system.

- Adequate Voltage:Ensure the pump receives the correct voltage to operate efficiently. Insufficient voltage can lead to reduced performance and premature failure.

- Clean Fuel:Use clean fuel free of contaminants to prevent damage to the pump’s internal components.

- Regular Maintenance:Perform regular inspections and maintenance to ensure the pump is functioning correctly and replace any worn or damaged components.

Applications and Use Cases

12-volt electric fuel pumps find widespread applications across various industries and settings, offering efficient and reliable fuel delivery solutions. These pumps are commonly employed in automotive, marine, and industrial applications, each with unique requirements and challenges.

Automotive Applications

- Fuel Injection Systems:Electric fuel pumps play a crucial role in modern fuel injection systems, supplying a constant and precise fuel flow to the engine’s injectors.

- Fuel Transfer:Electric pumps are used to transfer fuel from the fuel tank to the engine’s fuel system, ensuring a steady supply during operation.

- Fuel Filtration:Electric pumps can be integrated with fuel filters to remove contaminants from the fuel, protecting the engine and fuel system components.

Marine Applications

- Outboard Motors:Electric fuel pumps provide fuel to outboard motors, powering boats and watercraft in various marine environments.

- Inboard Motors:Inboard boats utilize electric fuel pumps to deliver fuel to the engine, enabling efficient propulsion and performance.

- Fuel Transfer:Electric pumps are employed to transfer fuel between tanks or from portable containers to the boat’s fuel system.

Industrial Applications

- Industrial Machinery:Electric fuel pumps are used in industrial machinery such as generators, forklifts, and construction equipment, providing a reliable fuel supply for operation.

- Fuel Dispensing:Electric pumps are commonly found in fuel dispensers at gas stations, facilitating the efficient and controlled transfer of fuel into vehicles.

- Fuel Storage:Electric pumps are used in fuel storage systems to transfer fuel between tanks, maintain optimal levels, and facilitate fuel delivery.

Recent Advancements and Future Trends

The realm of 12-volt electric fuel pumps has witnessed significant advancements in recent years, paving the way for enhanced performance, efficiency, and reliability. Emerging trends and innovations are shaping the future of these crucial components.

Advanced Materials and Design

The industry is embracing cutting-edge materials and innovative designs to improve pump durability and longevity. Advanced composites and lightweight alloys enhance structural integrity while reducing weight, leading to improved fuel efficiency.

Integrated Electronics and Sensors

The integration of advanced electronics and sensors into electric fuel pumps is transforming their functionality. Embedded microcontrollers enable precise control of fuel pressure and flow, optimizing engine performance and reducing emissions. Integrated sensors provide real-time monitoring of fuel system parameters, allowing for proactive diagnostics and maintenance.

Variable Speed Control

Variable speed control technology allows electric fuel pumps to adjust their output based on engine demand. This dynamic adjustment enhances fuel economy, reduces noise levels, and improves overall system efficiency.

Future Applications and Developments

The future of 12-volt electric fuel pumps holds exciting possibilities. Advancements in electrification and autonomous driving are driving the development of pumps tailored for electric and hybrid vehicles. Additionally, research into alternative fuels, such as hydrogen and biofuels, is opening new avenues for innovation in fuel pump technology.

Final Review

As we conclude our exploration of 12 volt electric fuel pumps, we hope you have gained a deeper understanding of their vital role in modern fuel systems. These pumps have revolutionized fuel delivery, offering efficiency, reliability, and performance that was once unimaginable.

As technology continues to advance, we can expect even more innovation in the field of electric fuel pumps, further enhancing their capabilities and applications.

We encourage you to continue your learning journey by exploring the resources available online and consulting with experts in the field. With the knowledge you have gained today, you are well-equipped to make informed decisions about 12 volt electric fuel pumps and ensure optimal performance for your engine.

Popular Questions

What are the advantages of using a 12 volt electric fuel pump over a mechanical fuel pump?

Electric fuel pumps offer several advantages over mechanical fuel pumps, including:

These advantages make electric fuel pumps the preferred choice for many modern fuel systems.

How do I choose the right 12 volt electric fuel pump for my application?

When selecting a 12 volt electric fuel pump, consider the following factors:

Matching the fuel pump to your specific application will ensure optimal performance and reliability.

How often should I replace my 12 volt electric fuel pump?

The lifespan of a 12 volt electric fuel pump can vary depending on factors such as fuel quality, operating conditions, and maintenance. However, as a general guideline, most electric fuel pumps should be replaced every 5-7 years or as recommended by the manufacturer.